The Process of Coin Minting

From Raw Metals to Gleaming Tokens of Trade

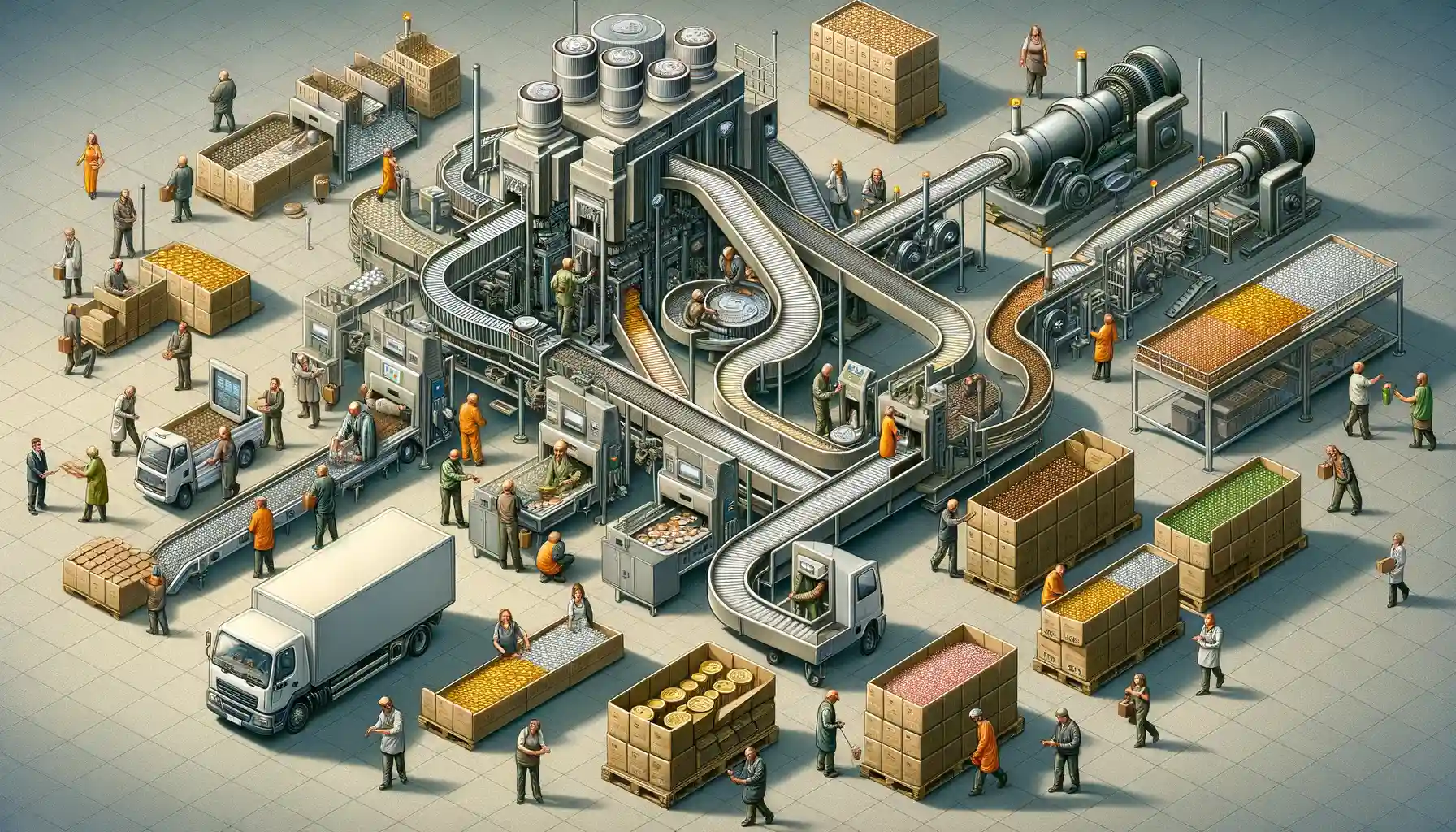

The minting of a coin starts with raw metals, a mix of practicality and alchemy. Imagine sheets of shimmering alloys—copper, nickel, or zinc—rolled out like dough waiting to be transformed. These metals are the unsung heroes that give coins their strength and brilliance. They’re cut into blank circles, known as blanks or planchets, which look like tiny, unpolished mirrors of potential.

The real magic happens when these blanks meet the dies—engraved molds that imprint each coin with its iconic design. The press slams down with unimaginable force (we’re talking hundreds of tons!), embossing every intricate detail, from the sturdy ridges along the edge to the face of a famous figure or national emblem. Suddenly, a mere piece of metal becomes a visual storyteller, ready to hold value in your hands.

The Small Touches That Make Coins Unforgettable

But don’t think coins are rushed through assembly. Oh no! Each one is polished, washed, and prepared with care, almost as if they’re about to step onto a stage. Here’s how:

- Burnishing: A polishing process makes sure your coins shine like stars.

- Edge lettering or grooves: Little details added to foil counterfeiters—and speak of precision craftsmanship.

Every step echoes centuries of tradition and innovation. It’s artistry you can carry in your pocket.

Quality Control in Coin Production

Precision Meets Perfection: The Heart of Coin Quality

Each coin begins its journey to the world with one mission: to embody perfection. Once the raw metal is transformed into a shiny disk of value, it must face its toughest critic—quality control. Imagine this step as a coin’s ultimate audition before taking center stage in our wallets and pockets.

Here, every detail matters. Machines equipped with laser-like focus inspect each coin for flaws like off-center strikes or uneven edges. But wait—it’s not all up to the machines. Human experts, with their eagle eyes and years of expertise, step in where technology ends. They scrutinize for those ever-so-tiny imperfections a machine might miss.

- Are the inscriptions crisp and legible?

- Does the luster meet the mint’s high standards?

- Are the dimensions exact, down to the millimeter?

Don’t be fooled—this isn’t just about aesthetics. A poorly minted coin can disrupt vending machines or payment systems. And who wants a coin that doesn’t pull its weight? The stakes are high, but the reward? A flawless piece of craftsmanship ready to circulate the world.

Stress Tests: Pushing Coins to Their Limits

Before a coin ever lands in your palm, it undergoes grueling tests to prove its durability. Think of it as boot camp for currency. Coins are struck, dropped, even scratched to simulate years of wear. Will it survive rubbing against keys in your pocket? Can it still shine after being tossed into a fountain?

These trials ensure every coin’s lifetime as a workhorse of commerce. It’s no exaggeration to say durability is king—coins need to endure decades without losing their shape, shine, or value. Seeing this process in action reminds you: behind every seemingly simple coin is a symphony of care, precision, and resilience.

Distribution Channels for Coins

From the Mint to Your Wallet: How Coins Travel

Ever wondered how a shiny new coin reaches your fingertips? It’s a journey that rivals any great adventure, involving precision, careful planning, and plenty of pit stops. Once coins are minted and pass rigorous quality checks, they’re handed over to central distribution facilities. Think of these as the “hubs” in a giant spider web, where coins are sent out to conquer commerce.

Coins don’t just meander their way across the country, though. They’re packed into secure containers and whisked away by armored transport companies—imagine them as VIP passengers in bulletproof limousines. From there, they find their way to various destinations, such as:

- Banks and financial institutions – the backbone of everyday transactions, ensuring coins circulate smoothly.

- Retailers and businesses – think vending machine operators, tollbooth services, or industries needing change-heavy cash flows.

- Coin collectors – avid enthusiasts who snag limited editions directly from mints or dealers.

It’s incredible to think that these tiny discs of metal embark on such a complex logistical network before jingling in your pocket. Every coin has a story—not just its design, but also its incredible odyssey!

The Role of Banks in Coin Circulation

How Banks Keep Coins Moving

Ever wonder how that shiny nickel or sturdy quarter ends up jingling in your pocket? Banks play a behind-the-scenes role that’s nothing short of fascinating. They’re like the choreographers of the intricate dance called coin circulation, ensuring these tiny metal heroes are always where they’re needed most.

When new coins leave the mint, they don’t just march directly into public hands. No, first stop: banks. These institutions act as the middlemen, bridging the gap between freshly minted coins and everyday transactions. Imagine them as treasure vaults that prepare for deployment to local businesses, vending machines, and—yes—your wallet.

- Commercial Banks: Your local bank receives bulk deliveries of coins and then redistributes them to retailers, gas stations, and more.

- Central Banks: They manage the overall flow, ensuring regions have the right balance of coins to keep markets humming.

But here’s the kicker: banks don’t just distribute—they also usher worn-out coins back into the system, sending damaged ones on a one-way trip to the mint for recycling. Every time you deposit a jar full of pennies, the banking system ensures those coins can live to see another cash register—or retire gracefully.

Challenges and Innovations in Coin Lifecycle

Unforeseen Hurdles in a Coin’s Journey

Ever thought about how a humble dime or penny fights its own battles? It’s not all smooth sailing from the mint to your pocket. One of the biggest headaches is wear and tear. Coins circulate for decades, jingling in pockets, rolling under vending machines, and braving corrosive environments. Over time, many become illegible, bent, or downright unusable. Imagine trying to pay with a washed-out coin that’s seen one too many laundry cycles—awkward!

There’s also the issue of counterfeiting. While digital scams may grab headlines, physical currency isn’t spared. For every ingenious coin design, there’s someone keen on mimicking it for profit. Tackling this requires advanced technologies like laser etching and micro-engraving—tiny details that the naked eye might miss but prove a coin’s authenticity.

The Bold Innovations Keeping Coins Relevant

Thankfully, innovation races ahead of these challenges! Modern coins are evolving into tech-savvy marvels. Some countries are experimenting with bi-metallic designs, combining different metals for durability and security. Others are embedding RFID chips into high-value coins to track circulation—a nod to merging traditional money with futuristic tech.

And let’s not forget the effort to make coins more eco-friendly. Mints are testing recycled metal alloys and sustainable production methods. The goal? A smaller ecological footprint without sacrificing quality.

The next time you hold a shiny quarter, think of it as a tiny, resilient superhero.