The History of Coin Minting

From Hammer Strikes to Precision Machines

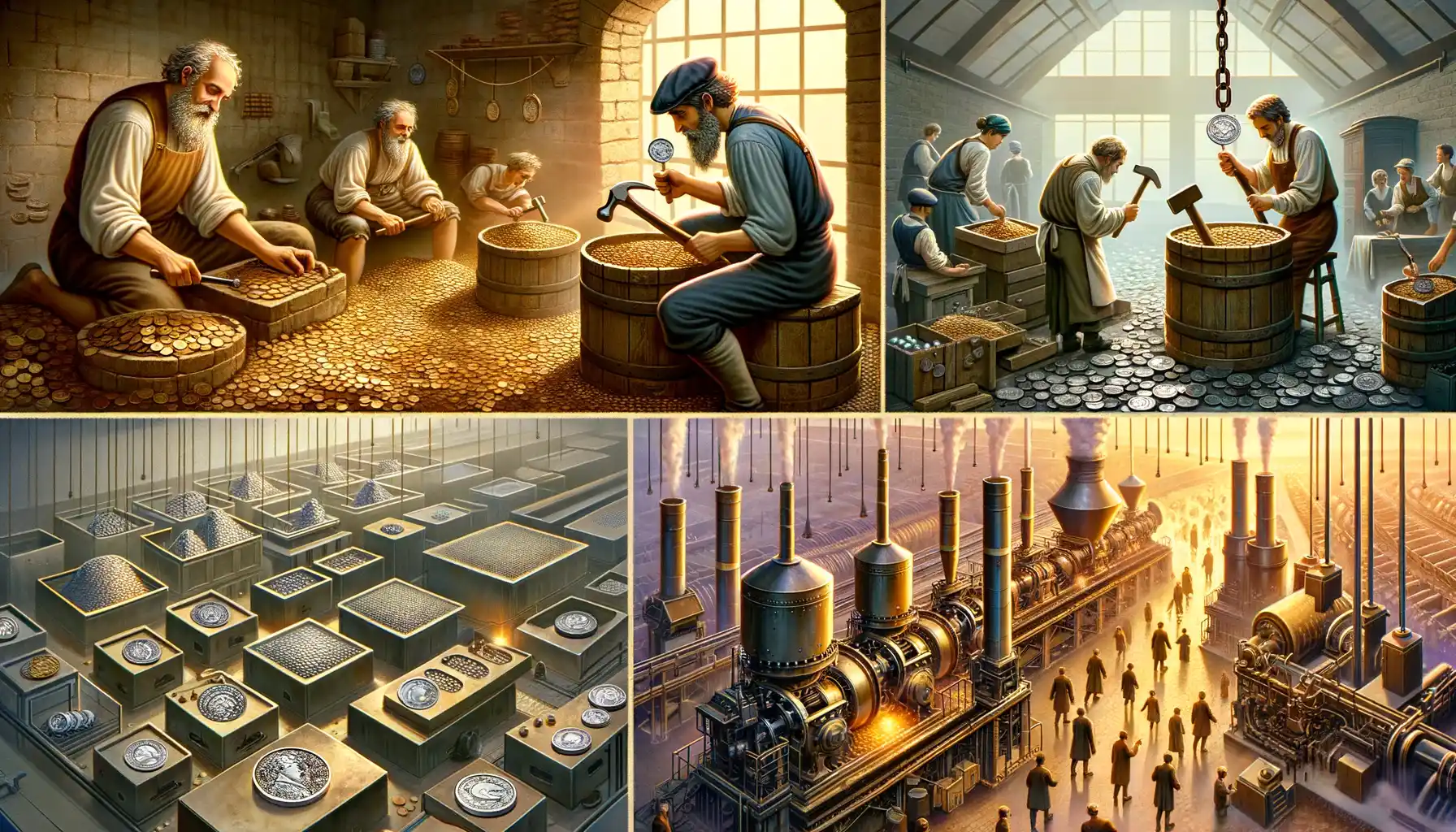

Picture this: the clang of a hammer striking heated metal, sparks flying into the air. That’s how coin minting began—raw, loud, and breathtakingly human. Ancient civilizations like the Greeks and Persians hand-struck coins one by one, using molds and punches. Each strike carried not just the image of a ruler or deity but also an artisan’s unique touch. No two coins were truly identical.

Fast forward a few centuries, and the Middle Ages brought in screw presses. Imagine enormous wooden contraptions powered by humans—or sometimes even animals—neatly stamping coins with designs more intricate than ever before. These presses were revolutionary but still slow, labor-intensive, and often imprecise.

- In ancient China, bronze casting emerged, producing coins with elegant square holes for easy stringing.

- The Renaissance saw a leap forward: steam-powered coin presses, capable of churning out uniform currency at remarkable speed.

What’s fascinating is that coin minting isn’t just technology evolving—it’s art adapting to the times. Think about it: every coin carries its era’s ambition, whether it’s Julius Caesar’s profile or a modern state’s national emblem. It’s history you can hold in your palm.

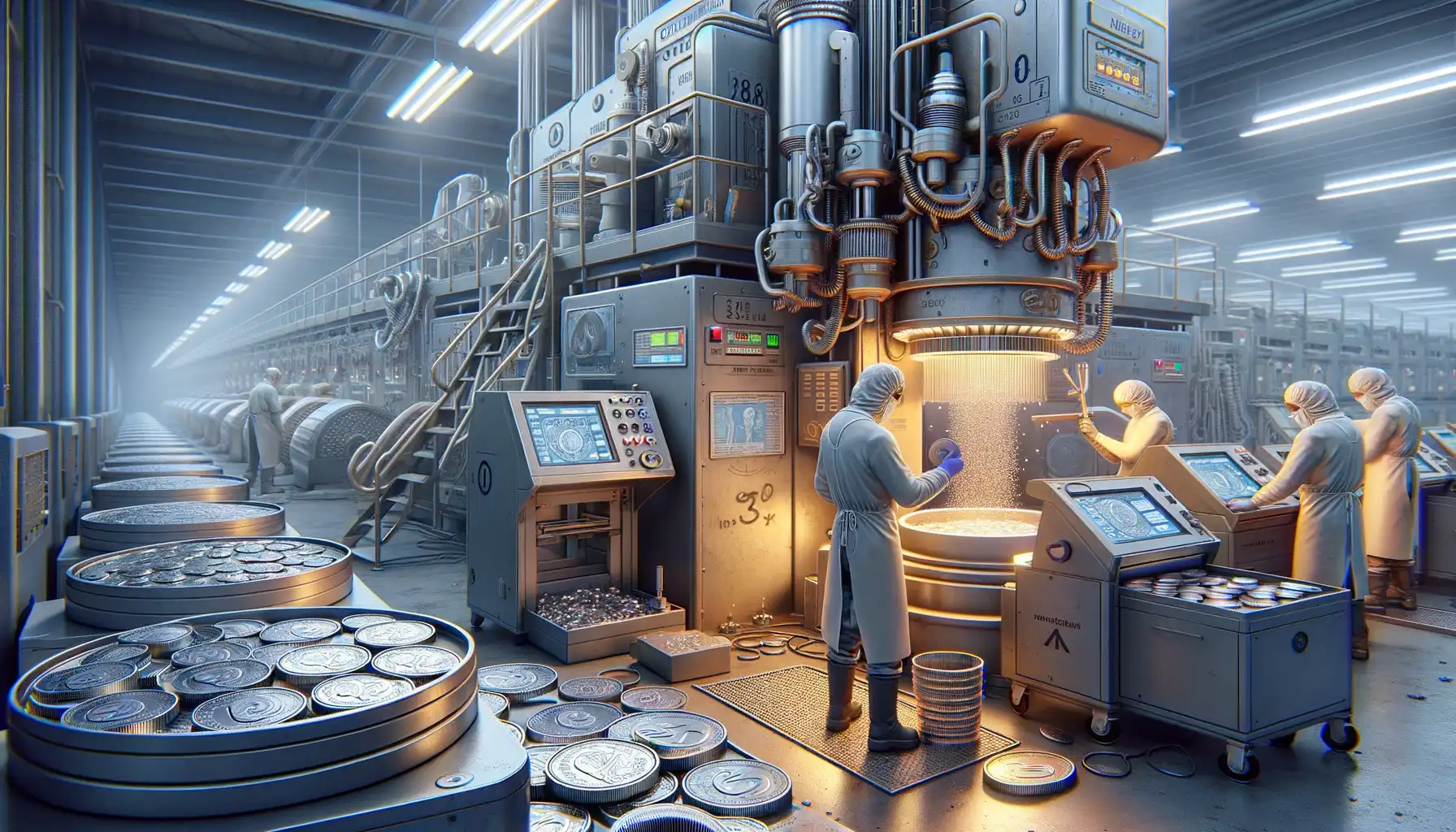

Modern Techniques in Coin Production

The Magic Behind Precision

Imagine holding a coin shimmering in the light—a small masterpiece of detail and brilliance. In today’s minting industry, this isn’t left to chance. Modern techniques are like the heartbeat of precision engineering, turning raw metals into works of art that tell stories. For instance, a method called computer-aided design (CAD) allows engravers to perfect every microscopic groove of a coin long before metal meets press. What once took months by hand can now be achieved with unmatched accuracy in days!

Mints today also rely on laser engraving, a technology so precise it feels almost futuristic. Lasers carve designs at a level where even a strand of hair looks clumsy in comparison. Now think about color—yes, coins have gone technicolor! Advanced techniques such as pad printing and multi-metal layering create coins with stunning hues, blending tradition and innovation effortlessly.

- High-speed presses can produce up to 800 coins per minute without sacrificing quality.

- Specialized coatings make coins more durable, protecting designs from wear and tear for decades.

Coins aren’t just currency anymore; they’re pieces of history, frozen in metal.

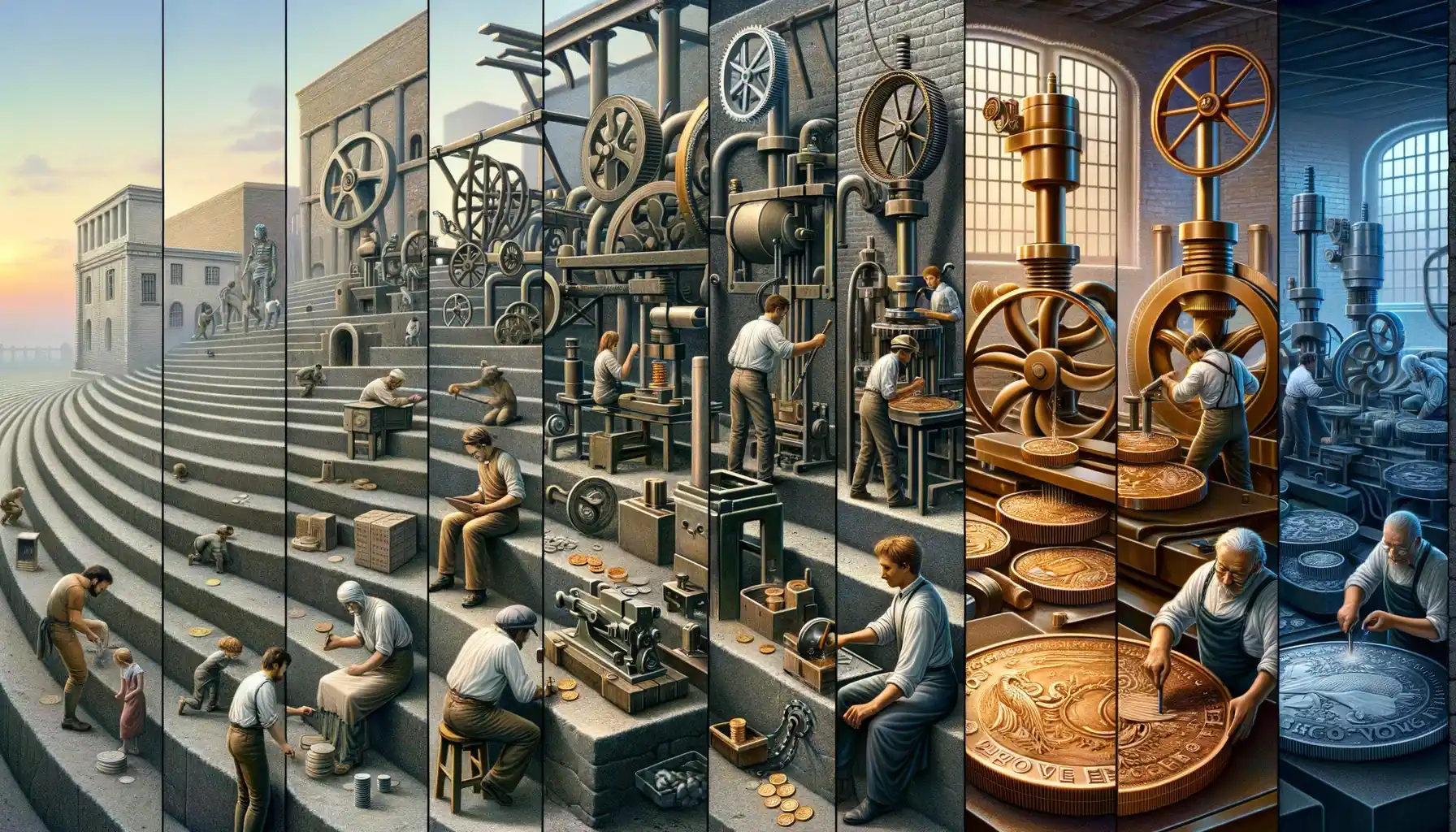

Key Innovations in Coin Minting Over Time

The Era of Hand-Hammered Perfection

The earliest days of coin minting were nothing short of mesmerizing. Imagine this: a skilled artisan, hammer in hand, striking raw metal blanks one at a time to imprint designs. Each strike was a delicate dance of precision and strength! These hand-hammered coins, dating back to ancient Greece and Rome, weren’t just currency—they were miniature works of art, boasting intricate patterns that carried cultural pride. But naturally, flaws were common; uneven edges and partial imprints meant perfection was rare, making each piece unique. It’s a quaint reminder of how far we’ve come.

The Revolution of the Screw Press and Beyond

Fast forward to the 1500s, and along came the screw press, an invention that shook the minting world—literally. With its twisting mechanism powered by strong arms (or sometimes entire teams of workers), coins became more uniform and detailed. Suddenly, royal faces and ornate symbols appeared sharper and more defined.

Then, as if turning the page of a gripping novel, steam-powered presses swept in during the Industrial Revolution, replacing muscle with machinery.

Key innovations also included:

- Milled edges to deter shady coin clipping—a trick savvier than you’d expect!

- Mass production techniques, allowing economies to flourish like never before.

Through it all, every leap forward was a step toward the gleaming coins jingling in your pocket today.

Challenges in Coin Minting Throughout History

Unpredictable Obstacles in Ancient Minting

Imagine a craftsman in ancient Greece, hunched over molten metal, gripping primitive tools with calloused hands. Coin minting wasn’t just a profession back then—it was an art form plagued by chaos. Without modern measurements or machines, the process depended heavily on human precision and luck. A single misstep could ruin an entire batch of coins—a huge loss when each ounce of silver or gold was priceless.

But nature wasn’t kind to these early artisans either. Impurities in metals like copper made coins brittle, breaking apart under pressure during striking. And let’s not forget the sheer difficulty of building furnaces hot enough to melt precious metals—no easy feat when firewood and bellows were all you had!

Worse still, counterfeiting emerged as a constant shadow. In the Roman Empire, for example, forgers substituted base metals for silver, forcing mints to develop more intricate designs. The harder it became to mimic a coin, the safer economies remained.

The Age of War and Resource Scarcity

The middle ages brought their own set of troubles. Wars—and there were plenty—played havoc with coin production. Armies needed weapons more than money, so metals like iron and bronze were diverted, leaving little for minting.

Not to mention, traveling mints were sometimes required, as rulers minted coins directly in warzones. Can you imagine hauling molten metal and heavy equipment across medieval battlefields? Yet, this improvisation often led to lower-quality coins, riddled with imperfections.

Even peacetime held its problems. Kings who overspent in their courts often resorted to “debasing” coins—reducing their precious metal content. While it solved immediate resource issues, the result was public distrust. After all, how would you feel holding a coin that felt lighter and looked duller than your neighbor’s?

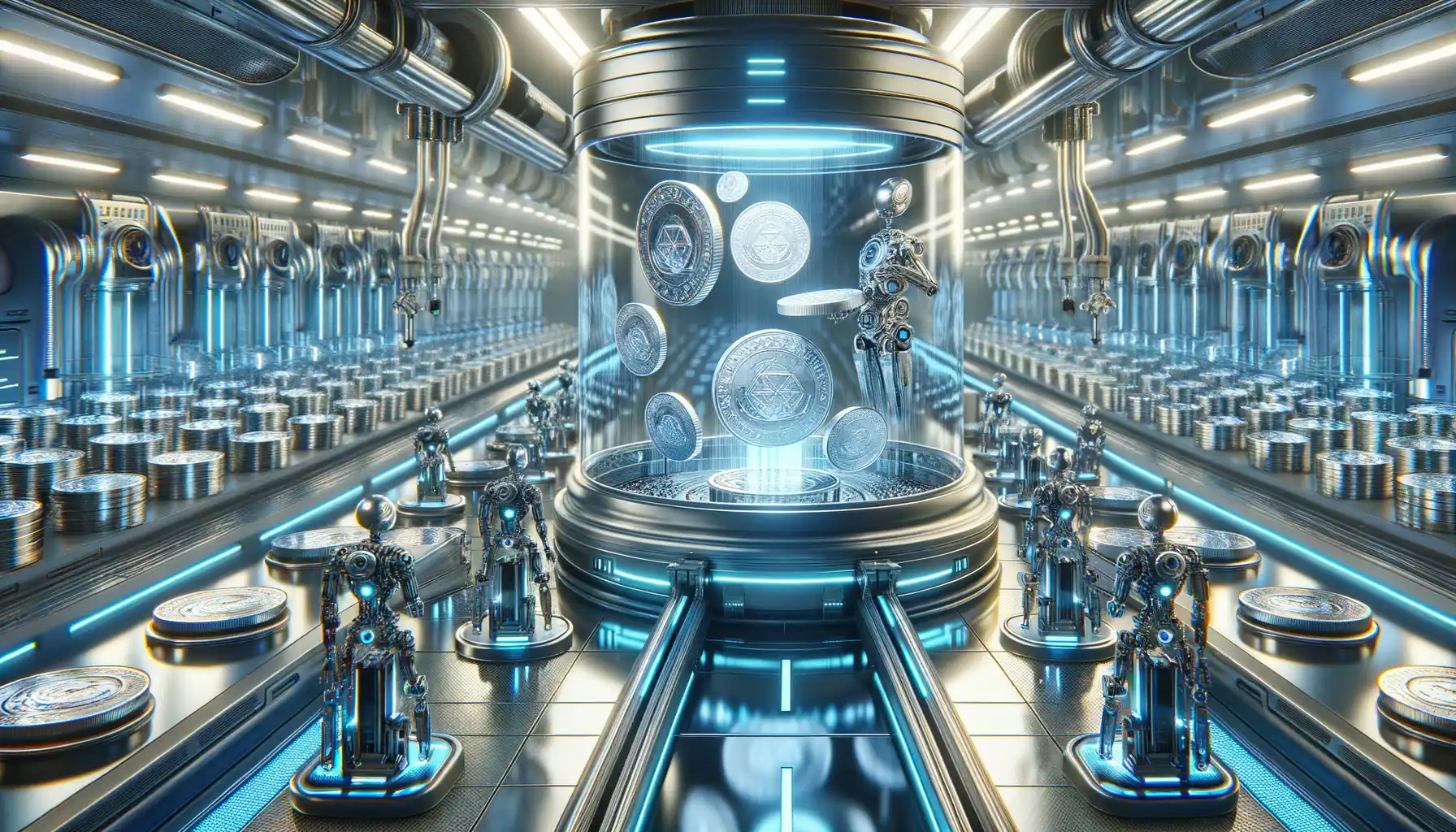

The Future of Coin Minting Technology

The Dawn of Smarter Coins

Imagine a coin that does more than just jingle in your pocket. The future of coin minting is hurtling toward a realm where technology meets artistry, creating coins that are practically alive with innovation. We’re talking about microchip-enhanced coins capable of storing data, verifying authenticity, or even interacting with digital wallets. Think of it as turning that humble little quarter into a pint-sized guardian of security and sophistication.

What’s driving this evolution? It’s a synergy of advanced materials, AI-driven design, and even nanotechnology. Picture coins so intricately crafted they defy counterfeiting but still gleam with elegance.

And beyond functionality? The aesthetic possibilities are limitless! Upcoming techniques may allow coins to transform under light or display holographic images. Could a coin become a miniature work of moving art? The potential is dazzling.

- Blockchain-integrated minting for enhanced traceability.

- Sustainable metals: coins made without environmental cost.

- Hyper-detailed textures you can feel with your fingertips.

Redefining the Coin Minting Experience

In the not-so-distant future, minting processes could become a spectacle open for public participation. Imagine designing your own coin through augmented reality interfaces or watching robotic arms engrave precise details live before your eyes! It’s no longer just production—it’s personalized artistry.

Governments and private mints alike are exploring collaboration with tech companies to bring this vision to life. Who knows? A coin no longer limited to physical uses might soon become a centerpiece of both commerce and culture.